Should I be embarrassed to even admit that I don’t own any kind of smartphone? I own a Kindle. Does that count? Somehow, I don’t think so.

But despite not being able to try this out for myself unless I borrow my brother-in-law’s iPhone or my niece’s Android phone, this is the first thing that has really tickled my fancy about smartphones (aside from Waze).

3 Test & Measurement Instruments You Can Create with a Smartphone Signal Generator, mixed signal… Click To Tweet

Test & Measurement Instruments

Anyway, back to the topic. I’m talking about turning your smartphone into a test & measurement instrument. Not a surprising development. And not that new, either. For some time now, we’ve been watching T&M instruments approach the size of smartphones. Handheld T&M instruments, while not necessarily offering the type of specs you’d find on a benchtop, have been finding their niche in the market as engineers are called upon more and more to leave their benches and go out into the field without the inconvenience of a heavy bag.

I don’t think smartphones are ruggedized enough yet to withstand the conditions that handheld T&M instruments are built for, although according to an article in the National Instruments Developer Zone, smartphones do have the potential to at the very least take over handheld meters in the field.

Anyway, let’s take a look at just a few sample products (there are many more out there), and see what we can measure with a smartphone.

The ‘Scope on a Phone

This should be a cinch, right? Simply show voltage over time? Yes, but what scope leads do you use? Do you need some sort of external hardware module? If you short two pins on your Device Under Test – will you fry your smartphone? What happens if your phone rings while you’re checking the output on pin 3 of your 7400? (I did not invent this question!)

In 2010, Onyx Apps introduced Oscilloscope 1.0 for iOS. The write-up on DailyAppShow describes the features and capabilities of this app, which can also generate sine, square, triangle, and sawtooth waveforms up to 22 kHz. Instead of using the audio input, which is somewhat limiting in terms of sampling and frequency, the Onyx scope app uses the microphone or a device plugged into the microphone input. Today, Version 1.9 is available. This app offers many of the typical features you would find on a desktop oscilloscope, such as triggering modes (Normal, Single, and Auto), screen capturing ability, reference signal calibration, and more.

The Mixed Signal ‘Scope on a Phone

Believe it or not!

How did they do that? We can thank Oscium for its Model iMSO-104 mixed signal oscilloscope (MSO) for iPad and iPhone, which consists of a module that includes one 8-bit analog channel and a four-input digital harness.

3 Test & Measurement Instruments You Can Create with a Smartphone Signal Generator, mixed signal… Click To Tweet

You might need something a little more serious for devices in the GHz range, but with a 5 MHz analog bandwidth, a sample rate of 12 MS, and the ability to instantly probe a circuit from a tiny device powered by an iPhone or iPad, who’s complaining? The software app is super user-friendly, replacing knobs and buttons easily with those adept key strokes and finger swipes.

Here are some interesting pointers I learned from the FAQ on the Oscium site:

- The analog channel can be used for measuring AC or DC. Maximum voltage range is -40 V to +40 V (10x mode).

- Digital threshold is 1.7 V (fixed).

- Triggering is available up to 100 ms. What’s really cool is that if your timescale goes higher, the triggering menu disappears. Although this can be scary when you first encounter this phenomenon, it’s a user-friendly tip once you’ve learned why or when this occurs.

- The IMSO-104 is supported by iOS version 5.0 or higher.

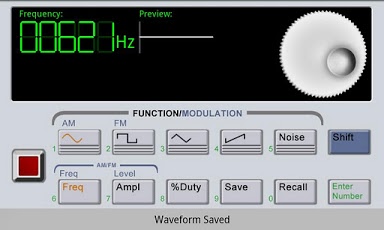

A Do-It-Yourself Signal Generator

Test & Measurement Instruments

An article that appeared this month in an EDN Network newsletter does not consider the 20 Hz to 20 kHz frequency range of a smartphone’s audio plug to be a limitation. There’s a lot you can do in this range. The article suggests that many of the components in medical devices fit into the lower end of the range. Here are some examples found on the National Instruments site:

- ECG (or EKG): 0.01 – 300 Hz

- EEG (electroencephalogram): 0.1 – 100 Hz

- EOG (electrooculograph): 0.1 – 10 Hz

- EMG (electromyograph): 50 Hz – 3 kHz

With the availability of hardware and software for less than $20 (not counting the cost of the smartphone!), and some light labor (get out your soldering iron) you can be up and running in no time with two channels (your left and right stereo connections) generating sine, square, and sawtooth signals.

Coffee always inspires! I remembered! The green baize scrubby thingy works wonders! Well, not exactly baize – more like a rough green plasticy sheet that feels gentler than sandpaper but works in the same way. After a thorough search for a piece of the green wonder (the coffee gave me the energy to do this), I found some of this treasure in the drawer at the bottom of a kitchen closet that only opens if all the other doors in the room are closed (Don’t even ask!). A few minutes inside my pot, after taking another rest to recover from the drawer/closet battle, and I could view my own reflection inside my suddenly-like-new pot!

Coffee always inspires! I remembered! The green baize scrubby thingy works wonders! Well, not exactly baize – more like a rough green plasticy sheet that feels gentler than sandpaper but works in the same way. After a thorough search for a piece of the green wonder (the coffee gave me the energy to do this), I found some of this treasure in the drawer at the bottom of a kitchen closet that only opens if all the other doors in the room are closed (Don’t even ask!). A few minutes inside my pot, after taking another rest to recover from the drawer/closet battle, and I could view my own reflection inside my suddenly-like-new pot!